Products

composite PTFE bushings metal-free ptfe plastic fiberglass bearing

- B-21 HIGH LOAD BEARINGS

- B-06 STANDARD TYPE BEARINGS

- B-03 GENERAL TYPE BEARINGS

- B-01 ECONOMIC BEARINGS

- Product description: composite PTFE bushings 50x58x50mm metal-free ptfe plastic fiberglass bearing

Filament Wound High Load Self-lubricating Bearings

FILAMENT-WOUND BEARING

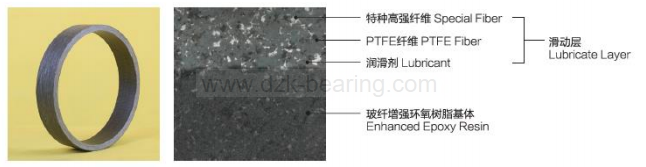

Material Structure:

High strength glass fiber with epoxy resin and the lubricating layer of it is PTFE wound fiber or special lubricating fiber.

Therefore,this special structure performs an outstanding anti-wear feature and low friction coefficient under high load and low speed condition. Furthermore, this absolutely new idea gives better solution for high load and excellent wear resistance possibility.

Typical Features:

1. Very high load capacity, Max.140Mpa

2. Very good chemical resistance

3. Lower friction and good wear properties,Friction coefficient<0.12

4. Long time dry operation without oil

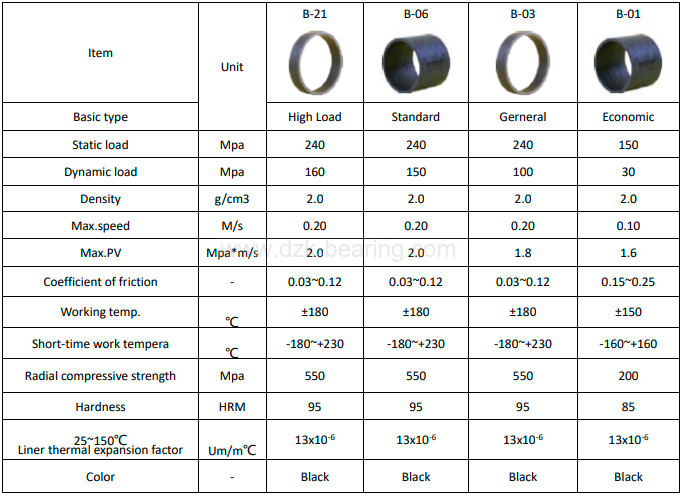

Material Data Sheet:

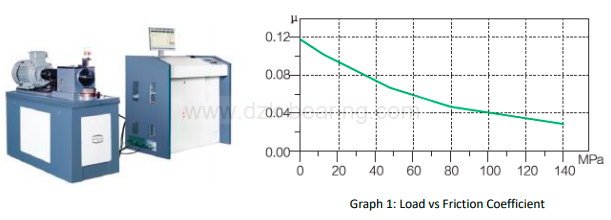

Friction Coefficient:

Friction coefficient of filament bearings is 0.03~0.12, the main factors affect the friction coefficient are load, moving method, speed and roughness of mating surfaces. Figure 1 shows the friction coefficient is going down while load is increasing under the rotation method.

Bearing Specification: J21-4050-40

Shaft: 45#HRC50,Ra=0.4

Load: 20~140MPa

Speed: 1.0m/min

Lubricate: Dry

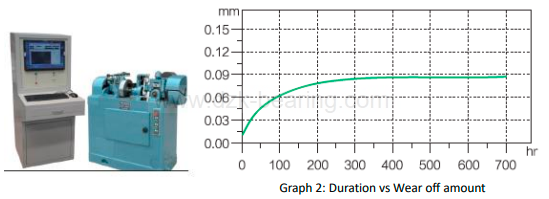

Anti-wear property:

The main factors affect the anti-wear property are the load,moving method,speed and roughness of mating surfaces. Figure 2 shows the bearing wear off under room temperature with the load of 50MPa when the bearing is swinging. It is found the wear off increases sharply during the initial running-in while the lubricant is transferred from the inner liner and a smooth surface is created there of to form the lubricating surface. After running-in period,it will maintain stable without wear off.

Bearing Specification: J21-3040-40

Shaft: 45#HRC50,Ra=0.4

Load: 50MPa

Speed: 1.0m/min,±45°

Lubricate: Dry

B-21 HIGH LOAD BEARINGS:

Material structure:

Lubricate layer: Continous wound PTFE and high-strength fibers encapsulated in an internally lubricated,high temperature filled epoxy resin.

Backing: continuous wound glass fiber encapsulated in a high temperature epoxy resin

Feature:

1. Very high load capacity

2. Excellent impact resistance

3. Nice chemical resistance

4. Low friction and good anti-wear properties

Technical Date:

|

Item |

Unit |

Date |

|

|

Max.Load |

Static load |

Mpa |

240 |

|

Dynamic load |

Mpa |

160 |

|

|

Max.Speed |

M/s |

0.20 |

|

|

Max.PV |

MPa*m/s |

2.0 |

|

|

Coefficient of friction |

- |

0.03~0.12 |

|

|

Working temp. |

℃ |

±180 |

|

Typical Application:

1. Port machinery

2. Lifting machinery

3. Package machinery

4. Hydraulic machinery

5. Construction machinery

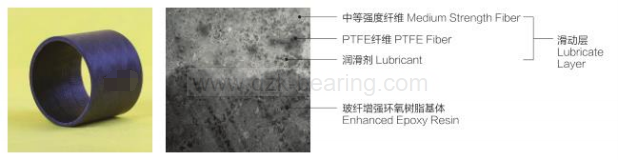

B-06 STANDARD TYPE BEARINGS:

Material structure:

Lubricate layer: Continous wound PTFE and medium-strength fibers encapsulated in an internally lubricated,high temperature filled epoxy resin.

Backing: continuous wound glass fiber encapsulated in a high temperature epoxy resin

Feature:

1. Medium to high load capacity

2. Good impact resistance

3. Nice chemical resistance

4. Low friction and good anti-wear properties

Technical Date:

|

Item |

Unit |

Date |

|

|

Max.Load |

Static load |

Mpa |

240 |

|

Dynamic load |

Mpa |

150 |

|

|

Max.Speed |

M/s |

0.20 |

|

|

Max.PV |

MPa*m/s |

2.0 |

|

|

Coefficient of friction |

- |

0.03~0.12 |

|

|

Working temp. |

℃ |

±180 |

|

Typical Application:

1. Port machinery

2. Lifting machinery

3. Package machinery

4. Hydraulic machinery

5. Construction machinery

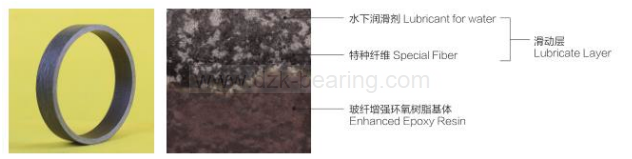

B-03 GENERAL TYPE BEARINGS:

Material structure:

Lubricate layer: Continous wound lubricant and sythetic fibers encapsulated in an internally liner.

Backing: continuous wound glass fiber encapsulated in a high temperature epoxy resin

Feature:

1. Medium to high load capacity

2. Good impact resistance

3. Average anti-wear feature

4. Low friction and good anti-wear properties

Technical Date:

|

Item |

Unit |

Date |

|

|

Max.Load |

Static load |

Mpa |

240 |

|

Dynamic load |

Mpa |

100 |

|

|

Max.Speed |

M/s |

0.20 |

|

|

Max.PV |

MPa*m/s |

1.8 |

|

|

Coefficient of friction |

- |

0.03~0.12 |

|

|

Working temp. |

℃ |

±180 |

|

Typical Application:

1. Food machinery

2. Air pump guide bushes

3. Ball and butterfly trunnion bearing

4. Hydraulic pressure machinery

5. Servo-motor bearing

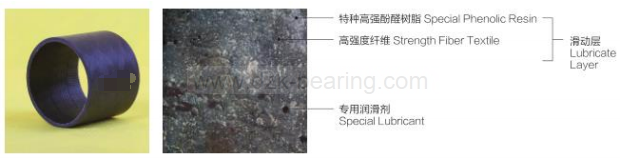

B-01 ECONOMIC BEARINGS:

Material structure:

This bearing material consist of fine woven cotton fabric reinforced phenolic composites.

Feature:

1. Relatively low load capacity

2. Relatively high friction

3. Suitable for oil lubricating applications

4. Average anti wear feature

5. Completely machinable

Technical Date:

|

Item |

Unit |

Date |

|

|

Max.Load |

Static load |

Mpa |

150 |

|

Dynamic load |

Mpa |

30 |

|

|

Max.Speed |

M/s |

0.10 |

|

|

Max.PV |

MPa*m/s |

1.6 |

|

|

Coefficient of friction |

- |

0.15~0.25 |

|

|

Working temp. |

℃ |

±150 |

|

Typical Application:

1. Food machinery

2. Air pump guide bushes

3. Ball and butterfly trunnion bearing

4. Hydraulic pressure machinery

5. Servo-motor bearing

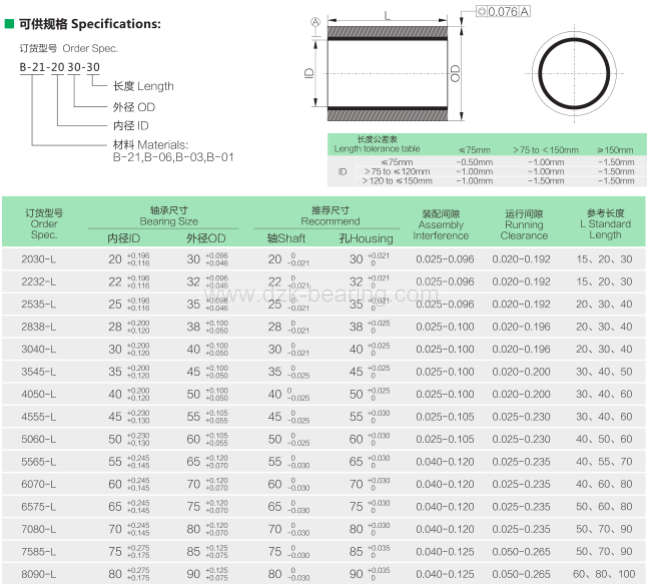

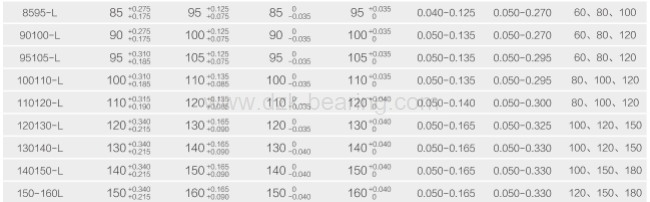

BEARINGS SIZE TABLE (WALL 2.5MM)

B SERIES TYPICAL APPLICATION

1. For high-speed motor car

2. For bike pedals,For fron shock aborbers

3. For medical wheelchair

4. For machine tools

5. For packing machinery

6. For wind powder generation

7. For conveyor system

8. For textile machinery

9. For robot

10. For automatic production line

11. For solar energy

12. For mining

13. For adjustment system

14. For digger

15. For scissor lifts

Latest News

Contact Us

Contact: Kai Wen

Phone: +86-13875823948

Tel: 008613875823948

Add: No.33,Changjiang (W) Road,Haian,Jiangsu